Pump Testing & Analysis

Driven by Data, Perfected in Pumps

Pump Design Services

We provide basic design assistance to all of our customers. Our aim is straightforward – to leverage our expertise and alert you to potential issues even before they arise.

The design support we offer includes, but isn’t limited to:

- Pump Selection: Determine the best fit for the application, whether Fixed or Variable Displacement, Vane, Gerotor, Spur Gear, or others.

- Gear Design: Addressing displacement and geometry.

- Porting Design: Options include unidirectional, reversing, and high-speed designs.

- Internal Clearances: Covering Axial, Journal, Gear, and more.

- Material Recommendations: Based on wear resistance, thermal expansion, and other factors.

Pump Analysis Services

We offer a range of advanced analysis services that allow for “virtual” product testing before moving on to prototype creation or mass production. Identifying these issues early in the process is cost-effective in the long run.

Our complimentary analysis services include:

- Determining pump power consumption based on internal clearances, fluid type, speed, pressure, and temperature

- Predicting flow ripples

- Preliminary cavitation forecasts

For more detailed insights, you may need more in-depth analysis. If so, our advanced analysis services cover:

FEA: Whether at the component or assembly level, including gears, shafts, and housings.

CFD: Addressing performance, flow, pressure ripple, aeration, cavitation, temperature increase, and resonance, among others.

.gif?width=800&height=600&name=Testing%20and%20Analysis%20GIF%20for%20NP%20Team%20(1).gif)

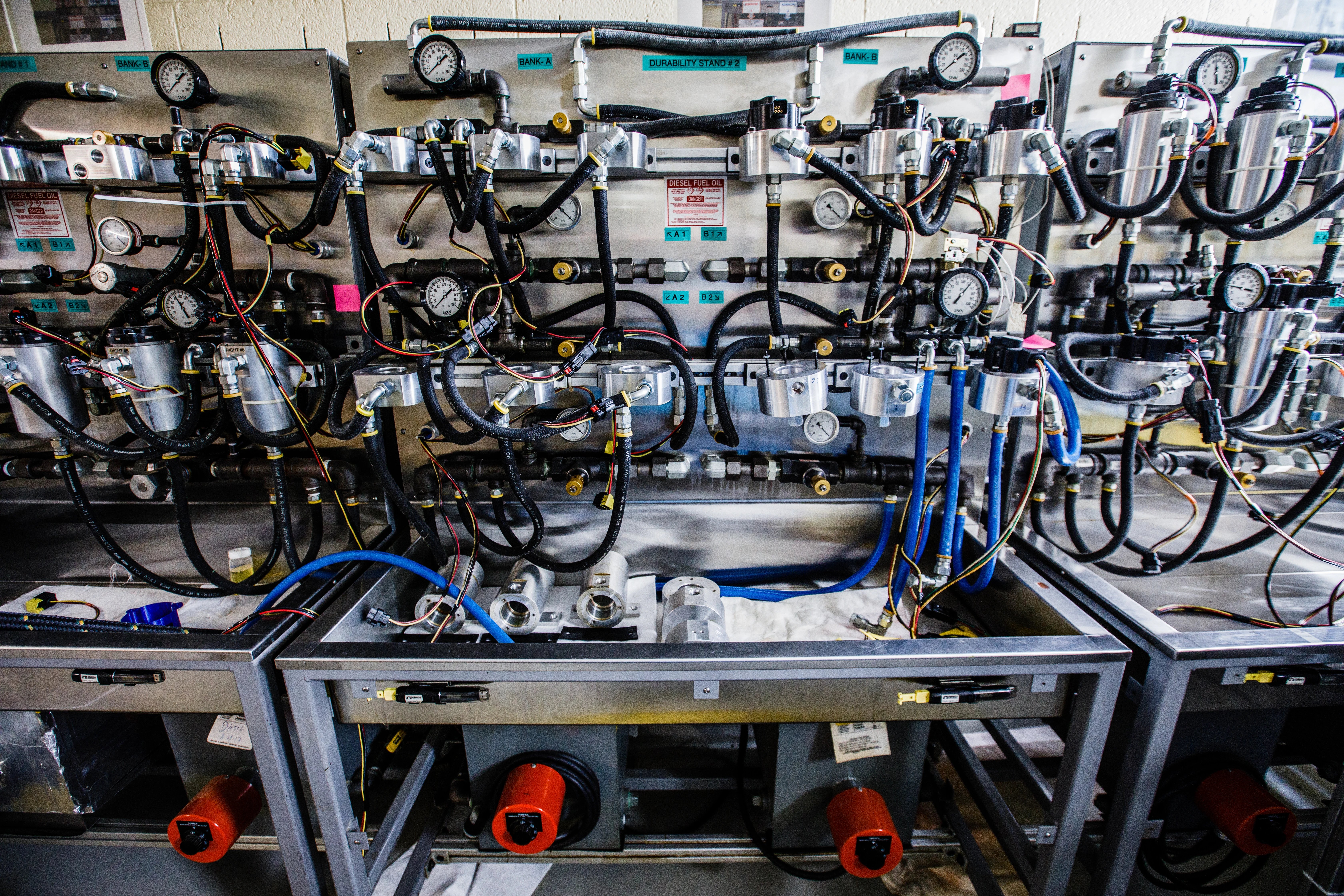

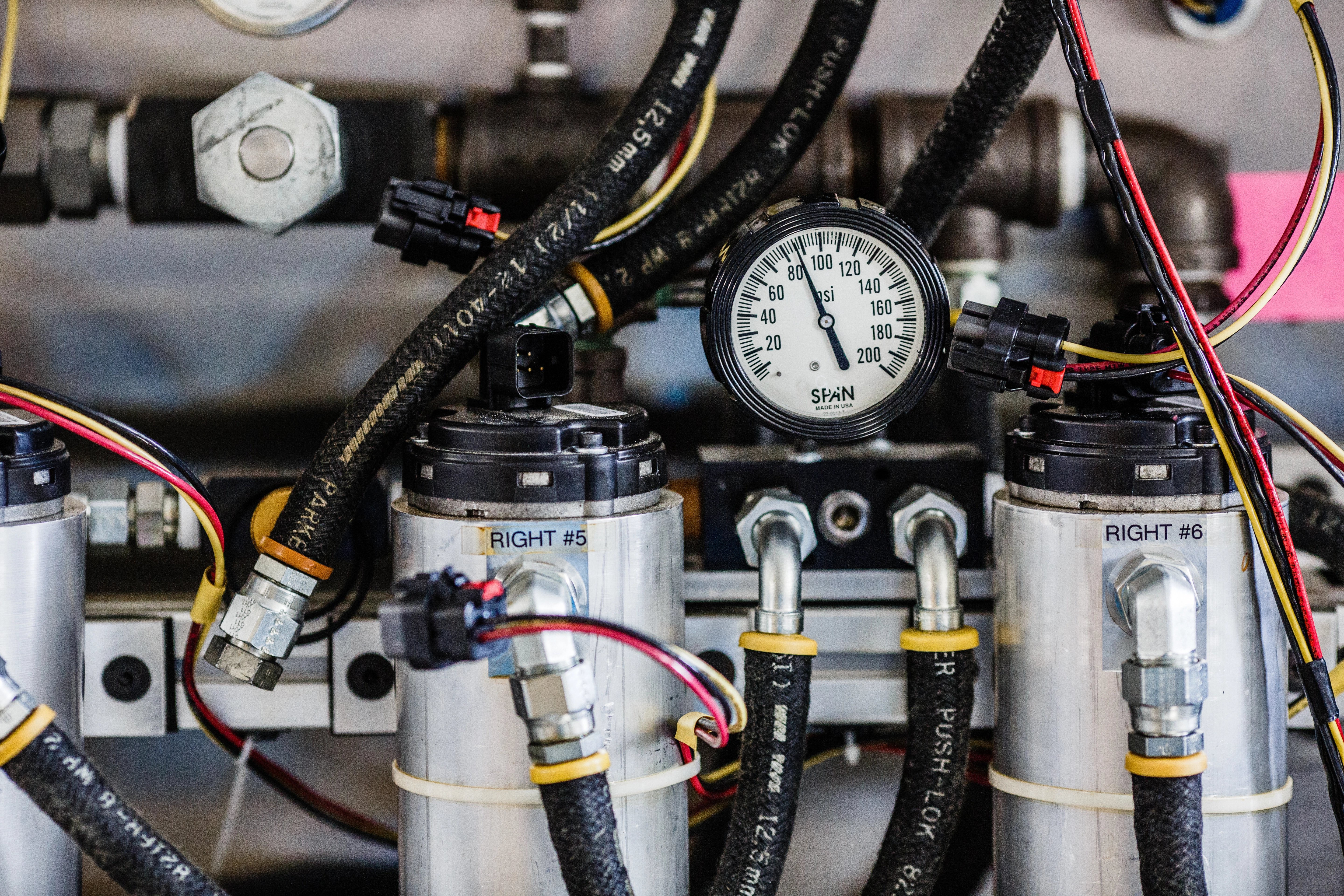

Development and Validation Testing

Leading automotive OEMs worldwide have engaged our testing services to enhance their R&D initiatives as well as their product development and validation processes.

If you have a requirement, it’s likely we can meet it. Our testing capabilities encompass:

- In-field engine lubrication and transmission flow assessments

- Pump performance evaluation and mapping

- Regulatory valve profiling

- Cold start simulations

- Studying the impact of inlet limitations and altitude on pump efficiency

- Contamination resilience assays

- Spring endurance examinations

- Journal-bearing threshold tests

- Both cyclic and steady-state endurance evaluations

- Resonance pinpointing and dwell analysis

- Varied vibration tests including Sine, Random, and Sine on Random

- Sound Power Intensity and Pressure Ripple Measurements

Why Implement Pump Testing & Analysis Services?

With a vast array of testing capabilities and specialized services implemented, your products will be propelled beyond compliance and pushed toward excellence.

At Nichols Portland, our wide range of testing capabilities and specialized services ensures your products surpass expectations. Our team is dedicated to helping you consistently outperform market standards.

Get Started with Pump Testing & Analysis

Related Resources

The Role of Low-Pressure Pumps in Fuel Injection Systems

What to Look for in a Gerotor Pump Manufacturer