Share this

Improving Pump Flow Rates & Efficiency

by Manasi Lakatos on Aug 3, 2023 11:42:18 AM

Functionally, pumps are simple.

When it comes to increasing flow rate and pump efficiency, not so much.

Determining how to maintain a high flow rate and efficiency is essential to ensure your pump is minimizing wear and tear and performing at full capacity.

Before we dive into improving pump efficiency, let’s dive into what pump efficiency is and how it works.

Understanding Pump Efficiency

First, let’s go with the most basic question on the topic: what is a pump?

Pumps are devices that move fluids, liquids, or gases, in a certain direction, typically in applications like engines or irrigation systems. Maintaining efficiency is essential to reduce energy consumption and costs.

What is Pump Efficiency?

On a high level, pump efficiency refers to how well a pump is able to convert one energy form to another – if the power entering the pump is equal to the power leaving the pump, the pump would reach 100% efficiency (something that’s impossible).

What is the Pump Flow Rate?

Flow rate is the volume of fluid that moves through a certain time period – typically calculated and measured using flow meters. It’s often confused for efficiency.

Pump efficiency and flow rate should be determined before choosing a pump, so it’s the best fit for your application.

5 Tips on Improving Pump Flow Rate and Efficiency

Because they go hand-in-hand, both pump flow rate and efficiency need to be at the forefront of your mind when working with pumps. Here are five tips to get started with improving pump flow rate and efficiency:

- Pump selection

- Maintaining the pump

- Check the impeller

- Install control systems

- Pump in parallel

1. Pump Selection

Different pumps have different flow rates and efficiencies, so choosing a pump specific to your application is necessary.

How do I choose a pump?

Pumps can come in many different shapes and sizes, but there are four main types of pumps:

- Gerotor pumps

- Hydraulic pumps

- Mechanical pumps

- Electric pumps

Engineers sometimes get in the mindset that bigger is better, which isn’t always the case. Oftentimes, pumps end up being oversized by 20-30%. This can cause unnecessary energy consumption as the pump would require more power from the motor than expected, therefore reducing efficiency.

How do I fix an oversized pump?

Trimming the impeller is a way to reduce the pressure and energy consumption caused by oversized pumps – causing efficiency improvements.

2. Maintaining the Pump

Imagine never changing the oil in your car. Eventually, the car would stop running because the engine would succumb to damage caused by friction.

The same concept applies to pumps. If you aren’t regularly applying lubrication to your pump, it will create friction and pump wear, which can cause efficiency losses from 10-25%. To prevent losses, pump maintenance is necessary.

How do I know when my pump needs maintenance?

Think of maintenance like your car inspection. Every component needs to be checked at regular intervals for wear and tear to ensure the pump is functioning properly. While wear and tear are inevitable, maintenance can help prevent costly, unexpected breaks in your pump.

What does pump maintenance consist of?

- Replacing worn parts like impellers

- Checking on the bearings

- Making sure enough lubrication is flowing throughout

- Inspecting any seals in the pump

When this maintenance isn’t improving performance and efficiency, it may be time to replace the pump.

3. Check the Impeller

Checking the impeller frequently outside of maintenance is necessary. The impeller is the part of the pump that actually moves the fluid. If it’s damaged, the pump could reduce the flow rate and efficiency, or even stop the pump completely.

4. Install Control Systems

Pump control systems regulate the flow rate and optimize energy efficiency. If only one pump is necessary to reach the desired flow rate, the control system will turn off the other pump until it’s needed again.

The most efficient way to control the pump flow rate is through Variable Frequency Drives (VFDs). VFDs control the motor’s speed to ensure it’s just enough for the flow requirements.

Since this control system doesn’t use any more energy than what’s needed, energy consumption and wear and tear on the pump are greatly reduced, making the pumps more efficient than most. VFDs are commonly found in the agricultural industry in irrigation systems where efficiency is crucial.

5. Pump in Parallel

If you’re only using one pump, chances are it isn’t at full efficiency and using an excessive amount of energy. When you implement a smaller, second pump, it takes on some of the workload, resulting in two pumps operating at optimum capacity.

Additionally, if one of your pumps stops working or is undergoing maintenance, you still have another pump available for operation.

What Should Your Pump Efficiency Rating Be?

Pump efficiency varies based on the type and size of pump you choose, as well as the motor. If you have a higher-quality pump with regular maintenance, efficiency can be above 90%. However, if you have a smaller pump or a pump that isn’t well maintained, it could be much less efficient.

The type of engine or motor you choose can also offer different levels of efficiency. While internal combustion engines have an efficiency of around 75-93%, AC motors typically run around 90% efficiency.

Whether the size of your pump or type of motor is affecting your efficiency, a good efficiency rating should maintain around 70-90%.

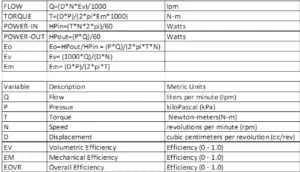

How to Calculate Pump Efficiency and Flow Rate

There are many ways to calculate pump efficiency and flow rate, some of the calculations include the following:

Getting Started with Maximizing Pump Efficiency

There are a variety of factors that impact the efficiency of your pump, and knowing where to start to increase your pump efficiency can be difficult.

Once you find the reason for inefficiency, getting started right away is essential to start saving costs, time, and energy spent.

Start Improving Your Pumps

When getting started on investing in efficiency, it’s best to consult with an expert to ensure you’re on the right track. Reach out to one of ours at Nichols Portland today.