Share this

Positive Displacement Pump Cavitation: What it Is and How to Avoid It

by Manasi Lakatos on May 1, 2023 5:53:09 AM

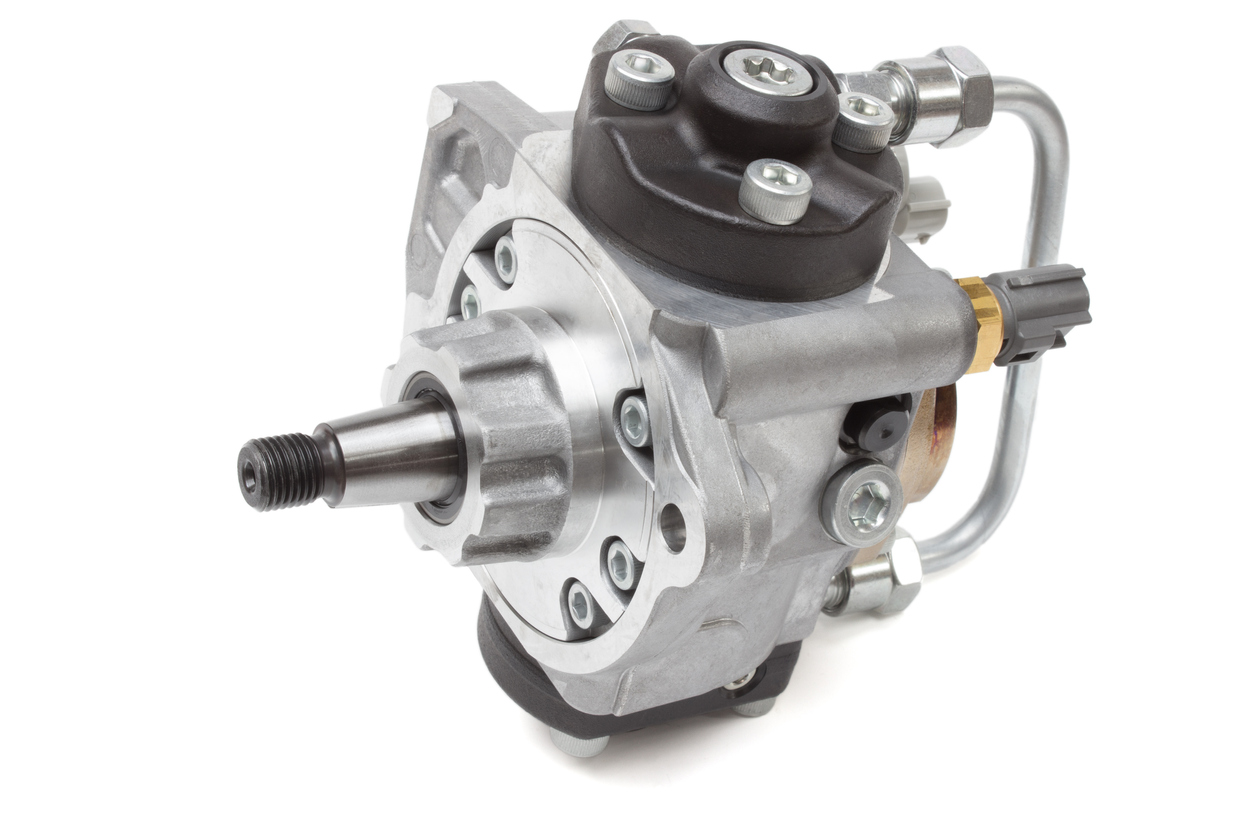

Positive displacement (PD) pumps are essential in numerous industries, including oil and gas, food processing, and pharmaceuticals, providing consistent and efficient fluid transfer. However, one common issue that can impact the performance and lifespan of your PD pump is cavitation.

Here, we explore the phenomenon of PD pump cavitation, its causes, consequences, and effective strategies to mitigate its occurrence.

What is Positive Displacement Pump Cavitation?

Cavitation is a phenomenon that occurs when the pressure in the pumped fluid falls below the fluid’s vapor pressure, causing the formation of vapor bubbles or cavities. As these bubbles travel through the pump, they collapse when they reach regions of higher pressure, releasing energy as shock waves. These shock waves can cause significant damage to the pump components, reduce efficiency, and increase noise and vibration levels.

What Causes Cavitation in Positive Displacement Pumps?

The main causes of cavitation in positive displacement pumps include:

- Insufficient Net Positive Suction Head (NPSH): NPSH is a measure of the energy available in the fluid at the pump inlet relative to the fluid’s vapor pressure. When the NPSH available (NPSHa) is less than the NPSH required by the pump (NPSHr), cavitation is likely to occur.

- High Viscosity Fluids: Pumping high-viscosity fluids can lead to increased resistance to flow, resulting in a pressure drop at the pump inlet, increasing the risk of cavitation.

- Inadequate Suction Piping Design: Improper design or installation of the suction piping system, including undersized piping, excessive pipe length, numerous bends or elbows, and partially closed or obstructed valves, can cause pressure losses and contribute to cavitation.

- Blocked or Clogged Filters/Strainers: Obstructions in filters or strainers can cause a pressure drop at the pump inlet, increasing the risk of cavitation.

- Pump Operating at High Speeds: When positive displacement pumps operate at high speeds, the time available for fluid to fill the pump chamber decreases, which can cause a pressure drop and promote cavitation.

- Inappropriate Pump Selection: Using a pump unsuitable for the specific application or fluid properties can lead to inadequate performance and an increased risk of cavitation.

- High-Altitude Operation: Pumps operating at higher altitudes have a lower atmospheric pressure, which reduces the available NPSH and increases the likelihood of cavitation.

- High-Fluid Temperature: Elevated fluid temperatures can lower the fluid’s vapor pressure, making it more susceptible to cavitation.

- Air or Gas Entrainment: The presence of air or gas in the fluid being pumped can reduce the fluid’s effective NPSH, increasing the risk of cavitation.

Ways to Address PD Pump Cavitation

The good news is that there are steps you can take to keep your PD pump running smoothly, including:

Ensure Adequate Net Positive Suction Head

To prevent cavitation, it is crucial to maintain an adequate NPSH. This can be achieved by reducing the suction lift, increasing the suction pipe diameter, or using a booster pump to increase the available pressure.

Select the Appropriate Pump

Choose a PD pump specifically designed for the fluid properties, system requirements, and operating conditions of your application. Consult with your pump manufacturer or engineers for proper pump selection.

Proper Pump Installation

Ensuring your PD pump is correctly installed, aligned, and connected to the piping system can help reduce the risk of cavitation.

Regular Maintenance

Regularly inspecting and maintaining your pump and its components can help identify early signs of cavitation and take corrective measures before significant damage occurs.

Monitor Pump Performance

Regularly monitoring pump performance indicators, such as flow rate, pressure, and temperature can help identify potential cavitation issues and enable proactive maintenance or system adjustments.

Determining the Speed of Pump Cavitation

Determining the speed at which a pump will begin to cavitate is a fairly complicated process. Numerous factors contribute to pump cavitation, including:

- Vapor pressure of the fluid (water, oil, gasoline)

- Available atmospheric pressure (sea level, higher altitude)

- Pressure losses in the inlet lines (length, diameter, surface roughness, momentum changes, turbulent flow, laminar flow)

- Pressure losses in the pump itself (length, diameter, surface roughness, momentum changes, turbulent flow, laminar flow, bypass circuit)

- Rotor geometry (diameter, chamber volume as a function of rotation, carry-over volumes)

- Pump’s operation speed

To determine the speed of pump cavitation, engineers use a combination of analytical methods, computer simulations, and experimental testing. Computational fluid dynamics (CFD) analysis can be a valuable tool to simulate fluid flow and pressure changes within the pump and the system, allowing you to identify potential cavitation risks and optimize the pump design and operating conditions to minimize cavitation.

In addition, conducting tests on physical pump prototypes and monitoring for signs of cavitation, such as noise, vibration, and reduced pump performance, can help confirm the theoretical predictions and refine the cavitation risk assessment.

Preventing Displacement Pump Cavitation

Understanding and addressing the causes of positive displacement pump cavitation are critical to maintaining the efficiency, reliability, and longevity of your pumping equipment. By following these steps, you can mitigate the risk of cavitation and maximize the performance of your PD pump systems.

Have any other questions on PD pumps or cavitation? – Reach out to one of our experts.